-

drsokodj - Stalni uporabnik

- Prispevkov: 529

- Pridružen: Sr nov 30, 2005 9:56 pm

-

Voith - Mojster foruma

- Prispevkov: 4113

- Pridružen: Če nov 13, 2003 12:22 pm

Spidojc je napisal/-a:Voith je napisal/-a:o fak sam ste pa naredl iz te teme eno godljo.

a sm gor lepo pastal odlicno resitev k se niti ni tok draga za ksnga k resno razmislja o tem.

vodni ic je mega resitev pa se ni to draga in lahk jih nastepas umes kokr mas placa.

pa gor je en napisu da se ic ne segreje.. ce se nebi grel pol nebi bil hladilnik.. fak logika pa taka

mah jest v tole tvojo, če prov zastopm, bl dvomm, voda je vseno segreta in nevem kolk kej ohlaja tole cev

Above you see an example of two THPs being used on a Porsche 944 Turbo. One THP is used after the turbocharger to reduce the temperature before entering the factory style air-to-air intercooler located in the front of the car. The second THP is added to pull additional temperature out of the intake charge before entering the intake manifold.

While this example is still in the final stages, and without coolant hoses routed, you see here where two THPs are used in parallel in place of a air-to-air intercooler on a Porsche 944 Turbo. The benefit here is where the factory intercooler flows 205 CFM at 28" of water column, this unit is estimated to flow over 500 CFM with the tubular end tanks in place. The pressure drop across this assembly is substantially less than your conventional type air-to air or air-to-water intercooler cores.

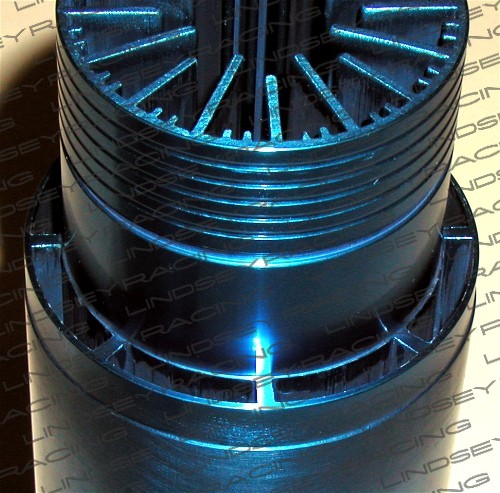

A low cost liquid/air heat exchanger solution. Designed and manufactured exclusively by Lindsey Racing, these "Thermal Hard Pipes" may be the answer you have been looking for.

The intended use is for cooling the intake charge air in turbocharged and supercharged applications. When you have plumbing from the compressor to the intake, these can replace that standard tubing plumbing and be used to cool the charge air at the same time.

You can use as a supplemental cooling solution in conjunction with an existing standard intercooler or as the sole primary cooling method.

This universal product allows you, the end user, to determine where and how you will implement it into your application. We provide the Thermal Hard Pipe, fittings, pumps and hose, and you take it from there to dream up and apply the solution.

Lindsey Racing's "Thermal Hard Pipes" are made from 6063 aluminum that is heat treated to a durable and rigid design. Pressed from a 500# billet, this extrusion is one of a kind. Described as a work of art, this functional heat exchanger is very adaptable. The inner passage has 37.15 inches of thermal exchange surface. So every inch of pipe has 37.15 square inches of heat exchange surface. Thus a 12 inch section has an incredible 445.80 square inches of transfer area. Almost hard to believe that it can be packed into a tube with an outside diameter of only 2.75".

We accomplished this with our "inside out" starburst design. We were daunted by the difficult task of turning this idea into reality. First thought not to be possible, we pressed our Extruder and Die Maker to find a solution. After many design revisions, compromises, and improvements, we ended up with a piece that was well beyond our original conception and expectations.

Around this 2.75" tube is another tube measuring 3.375". Between these tubes is a hollow passage. This void can be filled with water, glycol, gasses or other substances to "flush" the heat away from the inner tube.

Each end of the Thermal Hard Pipe is capped with a Fitting Collar. Each collar is tapped with "NPT" National Pipe Threaded holes. This allows you to attach one or multiple coolant supply and return lines to each Fitting Collar.

The Fitting Collars are designed to allow your coolant to circulate around the pipe and enter all of the 8 coolant channels. Whether you install as little as one inlet and outlet coolant line or several, the collar will deliver coolant to the entire tube. But.... the more coolant, the more cooling, so we gave you plenty of flexibility

-

croma_man - Mojster foruma

- Prispevkov: 4288

- Pridružen: So nov 02, 2002 10:42 pm

- Kraj: Celje

-

Voith - Mojster foruma

- Prispevkov: 4113

- Pridružen: Če nov 13, 2003 12:22 pm

croma_man je napisal/-a:povzetek, temperature drop = ... ?

nevem. nikjer ne omenjajo. pomoje je ta varianta z direktno vodo iz kilerja bolj jalova, sam cist posebi sistem bi znal bit pa zanimiv.

sta pa ta2 porsa k mata zgori tole namontiran oba cez 500konjska, tko da brez efekta tele cevi zihr niso..

-

drsokodj - Stalni uporabnik

- Prispevkov: 529

- Pridružen: Sr nov 30, 2005 9:56 pm

-

pinjas - Novinec

- Prispevkov: 411

- Pridružen: Ne feb 06, 2005 11:11 pm

- Kraj: Nova Gorica

- Spidojc

- Novinec

- Prispevkov: 487

- Pridružen: To nov 29, 2005 6:04 pm

- Kraj: ne veste tut ce povem

-

Voith - Mojster foruma

- Prispevkov: 4113

- Pridružen: Če nov 13, 2003 12:22 pm

ja ma cev ni bla razvita s strani nekih forumskih pametovalcev ampak priznanih tunerjev porschejev vusa - lindsey racing.

prednost pred navadnim intercoolerjem je to, da gre ta cev lahko tja kamor ic niti pod razno nemore it in to da ima veliko vecji pretok. lahko pa se v ekstremni situaciji zadeva hladi magar s co2 al pa tekocim dusikom.

in ne, slabsi pretok ni boljse delovanje.

pa to da iz dizl kombija poberes ic in ga das na avto je tut izjava vredna zlate medalje.

res cudn da se tega ne posluzujejo vsi k tunajo zadeve ampak grejo v nakupe 1000 evrskih icjev a?

prednost pred navadnim intercoolerjem je to, da gre ta cev lahko tja kamor ic niti pod razno nemore it in to da ima veliko vecji pretok. lahko pa se v ekstremni situaciji zadeva hladi magar s co2 al pa tekocim dusikom.

in ne, slabsi pretok ni boljse delovanje.

pa to da iz dizl kombija poberes ic in ga das na avto je tut izjava vredna zlate medalje.

res cudn da se tega ne posluzujejo vsi k tunajo zadeve ampak grejo v nakupe 1000 evrskih icjev a?

- Spidojc

- Novinec

- Prispevkov: 487

- Pridružen: To nov 29, 2005 6:04 pm

- Kraj: ne veste tut ce povem

sorry mudel sam za navadn avto je IC zih bolši,pa me prov zanima kolk je padec pritiska na drugi strani ICja ko že govoriš o pretoku,pa ker seriski avto ma tole notr,ok sej nerečm za kšn specijaln avto pa iz sodom co2ja zadi,sam tut to nevem če je računica,tole men še vedno zgleda bl tko k turbonator  k da 3 bare iz lahkoto

k da 3 bare iz lahkoto

Krvav'c je zakon

-

Voith - Mojster foruma

- Prispevkov: 4113

- Pridružen: Če nov 13, 2003 12:22 pm

Spidojc je napisal/-a:sorry mudel sam za navadn avto je IC zih bolši,pa me prov zanima kolk je padec pritiska na drugi strani ICja ko že govoriš o pretoku,pa ker seriski avto ma tole notr,ok sej nerečm za kšn specijaln avto pa iz sodom co2ja zadi,sam tut to nevem če je računica,tole men še vedno zgleda bl tko k turbonatork da 3 bare iz lahkoto

je al pa ni. odvisno od marsicesa.

ce je neki zadost dobr pol ni potrebe po razvijanju boljse stvari.. zgori ti pa tut pise primerjava pretoka med stock porsche icjem in temi cevmi. vec kot 2x vecji pretok imajo te cevi.

- Spidojc

- Novinec

- Prispevkov: 487

- Pridružen: To nov 29, 2005 6:04 pm

- Kraj: ne veste tut ce povem

Voith je napisal/-a:Spidojc je napisal/-a:sorry mudel sam za navadn avto je IC zih bolši,pa me prov zanima kolk je padec pritiska na drugi strani ICja ko že govoriš o pretoku,pa ker seriski avto ma tole notr,ok sej nerečm za kšn specijaln avto pa iz sodom co2ja zadi,sam tut to nevem če je računica,tole men še vedno zgleda bl tko k turbonatork da 3 bare iz lahkoto

je al pa ni. odvisno od marsicesa.

ce je neki zadost dobr pol ni potrebe po razvijanju boljse stvari.. zgori ti pa tut pise primerjava pretoka med stock porsche icjem in temi cevmi. vec kot 2x vecji pretok imajo te cevi.

pa sej ti pravm da se pretočnost komaj takrat pozna,če bi ti na izhodni strani ICja padel tlak(se pravi zabasan IC,ali pa da mašina prej poje tolk zraka kolikor ga sploh prihaja čez IC čeprov je na vhodni strani ICja zadosen tlak...),sam to se skoraj nebo zgodil,ker je cel sistem skos pod priiskom,bi mogel pa pritisk zmert na obeh straneh ICja pa bi videl da bi bil povsod enak,pri tej cevi,ki jo ti kažeš je edino mogoče manjša turbo luknja,ker mogoče pri ICju mal dlje (cca 0,1s) traja preden napolni sistem.zdej pa glej če maš uno cev pol rabš še dodatno en dovod nekaj mrzlega (voda,co2) se pravi še dodaten rezervar,pa ko ti zmanjka hladilnega medjia je cev brez pomena,medtem ko ti IC še vedno hladi

Krvav'c je zakon

-

drsokodj - Stalni uporabnik

- Prispevkov: 529

- Pridružen: Sr nov 30, 2005 9:56 pm

-

MikeLima - Novinec

- Prispevkov: 156

- Pridružen: Sr feb 06, 2008 6:47 pm

Po vrsti od dobrega proti slabemu, kakor jaz te reci vidim...

Vodni intercooler, samo rabis potem se en hladilnik za vodo, crpalko, primerneje za barke, ker tam hladna voda je naokoli kar sama po sebi... ZELO QL!

Velik intercooler posprican z vodo, uparilna toplota pa te reci... QL

Veliik intercooler OK

Sesanje zraka iz klime avta.. Jezesna, vroce v avtu pa okna morajo bit odprta...

Vbrizgavanje vode + metanol... Za znalce in mojstre, skoraj obvezen nek dirkaski ECU... MoTeC, Pectel, EFI....

Vbrizgavanje vode (kot pri fordu cosworth-u in mesersmithu) TRICKY!!

Suhi led na intercoolerju NE! Zmrzuje vlaga v intercoolerju, pa se prepustnost zmanjsa do nule. To je iz zgodbe pozabilismonavlagovzraku ali pa testiralismovarizonskipuscavikjerjefulsponaltlepanoce...

CO2 iz jeklenke tudi NE! Iz enakega razloga

Tekoci N (dusik) tudi NE! - " -

LP

Jest

Vodni intercooler, samo rabis potem se en hladilnik za vodo, crpalko, primerneje za barke, ker tam hladna voda je naokoli kar sama po sebi... ZELO QL!

Velik intercooler posprican z vodo, uparilna toplota pa te reci... QL

Veliik intercooler OK

Sesanje zraka iz klime avta.. Jezesna, vroce v avtu pa okna morajo bit odprta...

Vbrizgavanje vode + metanol... Za znalce in mojstre, skoraj obvezen nek dirkaski ECU... MoTeC, Pectel, EFI....

Vbrizgavanje vode (kot pri fordu cosworth-u in mesersmithu) TRICKY!!

Suhi led na intercoolerju NE! Zmrzuje vlaga v intercoolerju, pa se prepustnost zmanjsa do nule. To je iz zgodbe pozabilismonavlagovzraku ali pa testiralismovarizonskipuscavikjerjefulsponaltlepanoce...

CO2 iz jeklenke tudi NE! Iz enakega razloga

Tekoci N (dusik) tudi NE! - " -

LP

Jest

Kdo je prisoten

Po forumu brska: 0 registriranih uporabnikov in 2 gostov